why solar panel manufacturing factory need solar cell tester, and how it works

why solar panel manufacturing factory need solar cell tester, and how it works

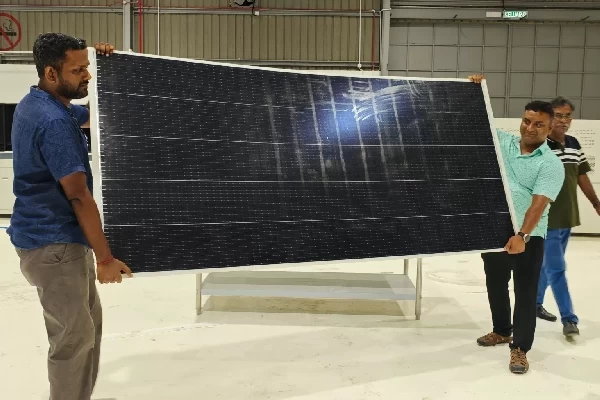

A solar panel manufacturing factory needs solar cell testers to ensure the quality and efficiency of the solar cells being produced. Solar cells are the building blocks of solar panels, and if they are not functioning optimally, the overall performance and durability of the solar panel will be compromised.

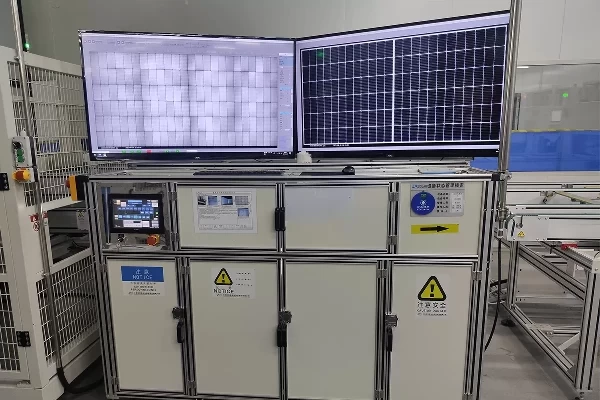

A solar cell tester is a piece of equipment that measures the electrical characteristics of a solar cell, including current, voltage, and efficiency. It is used to determine whether the solar cell meets the specifications for performance and quality, and to identify any defects that need to be addressed before the cell can be used in a solar panel.

Solar cell testers use a variety of techniques to measure the electrical properties of the solar cell, including flash testing and quantum efficiency testing. Flash testing involves exposing the solar cell to a brief, intense pulse of light, and measuring the resulting electrical response. Quantum efficiency testing involves measuring the cell's response to light of different wavelengths, to determine its efficiency at converting different wavelengths of light into electrical energy.

The solar cell tester also measures the open circuit voltage (Voc) and short circuit current (Isc) of the solar cell, which are key performance metrics used to evaluate the efficiency and power output of the cell. By measuring these characteristics, the tester can determine the maximum power point (MPP) of the cell, which is the point at which the cell generates the maximum amount of power.

In addition to detecting defects and ensuring performance, solar cell testers are also used to track the production of solar cells and to gather data for process control and optimization. By monitoring the performance of the solar cells over time, manufacturers can identify trends and make adjustments to the production process to improve efficiency and reduce defects.

Overall, a solar cell tester is an essential tool for any solar panel manufacturing factory that wants to ensure high-quality, efficient solar cells and panels. It provides critical information for quality control and process optimization, and helps to ensure that the end product meets the required specifications for performance and durability.

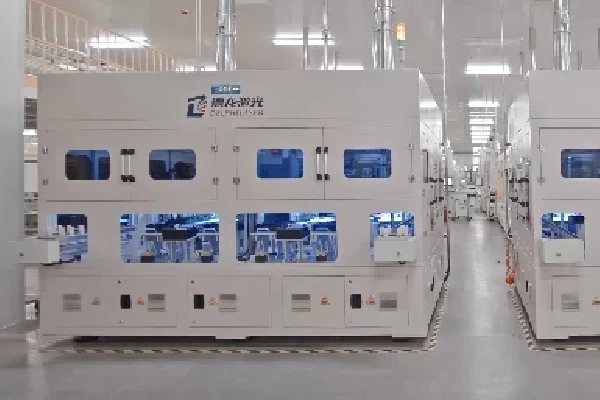

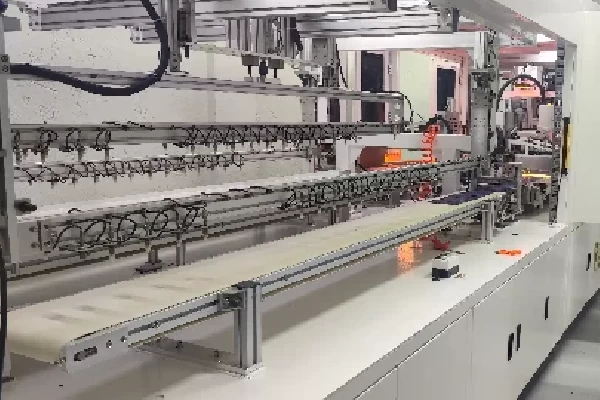

Non Destructive Cutting Machine Thermal Laser Separation Cutting Machine

cut cell to half, 1/3 1/4 1/5 1/6 1/7 1/8

Solar Cell IV Test before Tabbing